From healthcare to automotive, our gloves are tailored to meet the exact standards,

processes, and safety conditions of each industry.

“Built on deep industry understanding, strong R&D, in-house QA, and end-to-end traceability.”

Tailored glove solutions designed to meet the needs of your industry with precision, comfort, and safety.

Tailored gloves that meet the specific needs of each industry, ensuring safety, precision, and reliability.

Custom gloves for examinations, patient handling, surgical prep, and infection control.

Food-safe gloves that maintain hygiene and prevent contamination in handling and processing.

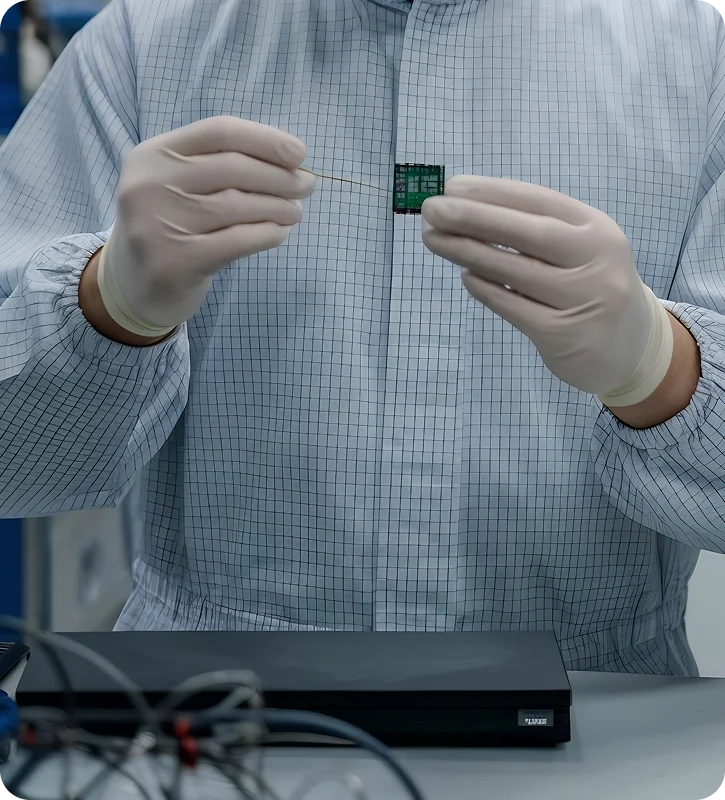

Built for sterile and cleanroom environments, our gloves safeguard against contamination while supporting precision work in drug development and lab operations.

Offering chemical and puncture resistance, our gloves provide reliable protection for scientists and lab technicians handling reagents and sensitive materials.

Engineered for grip and durability, our gloves protect workers from oils, solvents, and abrasives—ideal for assembly lines and repair environments.

Tough yet flexible, our gloves offer superior hand protection against mechanical risks, ensuring comfort and productivity across industrial processes.

Antistatic and powder-free options prevent contamination and protect delicate electronic components, ensuring precision in assembly and testing.

Requirement Discovery

Technical Evaluation

Prototype & Validation

Regulatory Documentation

Scale-Up & Supply Management

Discover how Anusham delivered tailored glove solutions to meet the unique needs of pharma, food processing, and automotive industries.

A multinational group with operations in Pharmaceuticals, Food Processing, and Automotive Component Manufacturing.

Each division required different glove specifications—sterile and thin for pharma, food-safe for wet environments, and high-grip for automotive assembly..

Enhanced chemical resistance, tactile precision, and low particulate gloves for lab workflows.

Reduced glove-related complaints by 47% Improved compliance readiness

Optimized procurement by consolidating suppliers under Anusham

In-house QA lab for continuous testing & validation.

In-house R&D to develop new formulations.

Traceability systems for full supply chain transparency

Strong manufacturing scalability to support high-volume orders

Deep understanding of cross-industry requirements

At Sri Anusham, we are committed to maintaining the highest standards in product quality, safety, and regulatory compliance. We continually invest in our manufacturing processes to meet evolving industry needs and ensure that our gloves deliver exceptional performance in the most demanding environments.

Thank you! Your message has been sent.